Table of Contents

- Introduction to Sway Bar Bushing symptoms

- Symptoms of faulty sway bar bushings

- Causes of sway bar bushing failure

- How to diagnose sway bar bushing problems

- How to fix sway bar bushing problems

- Upgrading to performance sway bar bushings

- Steps for replacing sway bar bushings

- Conclusion: The Importance of Maintaining Sway Bar Bushings for Vehicle Safety and Performance

- Frequently Asked Questions about the symptoms of Sway Bar Bushing.

Home » Sway Bar Bushing Symptoms: How to Tell if It Needs Replacement

Introduction to Sway Bar Bushing symptoms

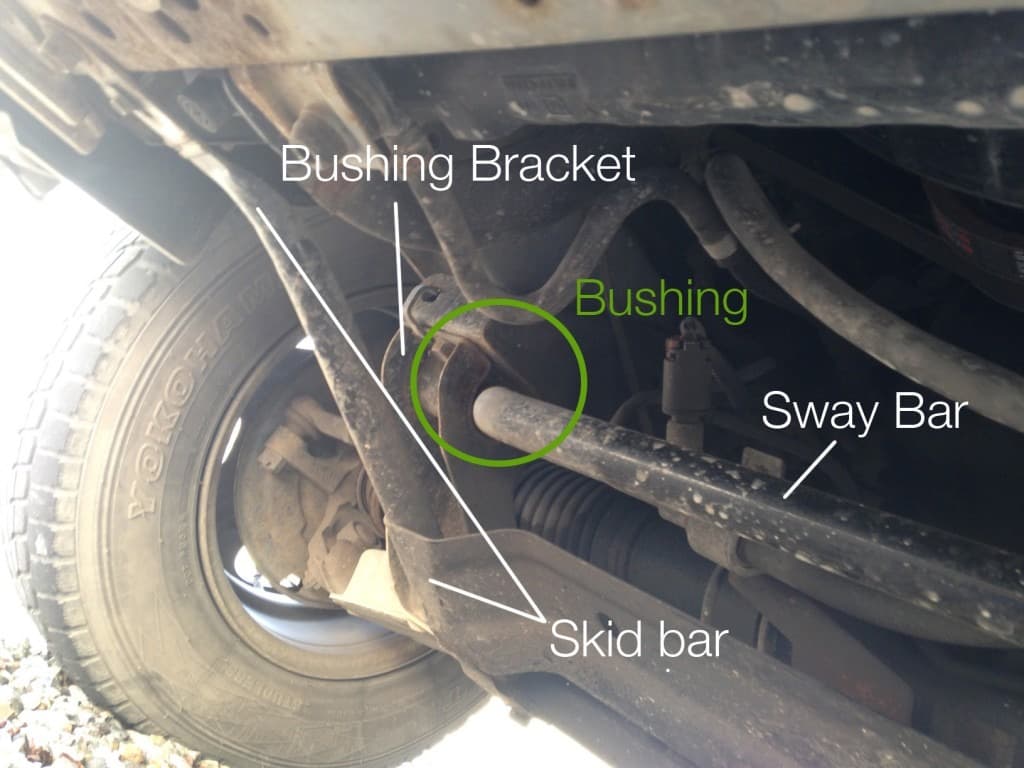

Sway bar bushings are an important component of a vehicle’s suspension system. Bar bushings isolate the bar from the frame and absorb shock as the vehicle travels over uneven roads. It is located between the sway bar (also known as the stabilizer bar or anti-roll bar) and the vehicle’s frame. These bushings help maintain the vehicle’s stability and handling, particularly when turning or driving over bumps.

Properly functioning sway bar bushings are crucial for ensuring the safety and handling of a vehicle. Unfortunately, sway bar bushings can wear out over time or become damaged due to road debris or accidents. When this happens, it can cause a range of issues that can affect the performance and safety of the vehicle.

Some common symptoms of faulty sway bar bushings include creaking, knocking, or clunking noises while turning or driving over bumps, handling issues such as the vehicle feeling loose or unstable while driving, and difficulty maintaining control in turns. Sometimes, sway bar bushings may also be visibly worn or damaged.

If you suspect that your sway bar bushings may be faulty, it’s important to diagnose and address the issue as soon as possible. This blog post will cover the symptoms of sway bar bushing problems, the causes of the failure, and how to diagnose and fix the issues. We’ll also discuss the benefits of upgrading to performance sway bar bushings and the steps involved in replacing sway bar bushings. By the end of this post, you’ll have a better understanding of sway bar bushings and how to identify and fix issues with these important components of your vehicle’s suspension system.

Symptoms of faulty sway bar bushings

One of the most common symptoms of faulty sway bar bushings is noise. Sway bar bushings worn or damaged may produce creaking, knocking, or clunking sounds while turning or driving over bumps. These noises may be more pronounced at higher speeds or when driving on rough roads.

Another symptom of faulty sway bar bushings is handling issues. If your sway bar bushings fail, you may notice that your vehicle feels loose or unstable while driving. This can make it difficult to maintain vehicle control, particularly when turning or driving over uneven surfaces. You may also notice that your vehicle “leans” more than usual when turning or bounces when driving over bumps.

If you can see that your sway bar bushings have cracks, torn, or otherwise damaged, this is a good indication that they need a replacement.

If you’re experiencing any symptoms, it’s a good idea to diagnose the issue as soon as possible. Ignoring the problem can further damage your sway bar bushings and other suspension components, which can be costly. In some cases, faulty sway bar bushings can also affect the safety of your vehicle, so it’s important to address the issue as soon as possible.

You can start by visually inspecting the bushings for visible wear or damage to diagnose sway bar bushing problems. You can also test drive the vehicle and pay attention to unusual noises or handling issues. It’s also good to check for worn sway bar links or other suspension components, which can contribute to sway bar bushing failure. Sometimes, you may need a mechanic to diagnose the issue. They will be able to identify the cause of the problem and recommend the appropriate course of action, whether replacing the sway bar bushings or performing other repairs.

Causes of sway bar bushing failure

Several factors can contribute to sway bar bushing failure. The most common cause is simply normal wear and tear over time. Sway bar bushings are subjected to a lot of stress and movement as the vehicle travels over uneven roads, and this can cause them to wear out over time.

Another cause of sway bar bushing failure is damage from road debris or accidents. If a rock or other debris strikes your sway bar bushings, it can cause damage that leads to failure. Similarly, if an accident affected the sway bar bushings, they may need to have a replacement.

Incorrect installation or lack of lubrication can also cause sway bar bushing failure. If the bushings are not properly installed or lubricated as recommended, they may fail prematurely. It’s important to follow the manufacturer’s instructions when installing sway bar bushings and to lubricate them as needed to ensure their longevity.

Regardless of the cause of sway bar bushing failure, diagnosing and addressing the issue as soon as possible is important. Neglecting faulty sway bar bushings can further damage your suspension system and negatively impact the handling and safety of your vehicle. If you’re experiencing sway bar bushing failure, be sure to have the issue diagnosed and repaired by a mechanic as soon as possible.

How to diagnose sway bar bushing problems

If you suspect that your sway bar bushings may be faulty, there are a few steps you can take to diagnose the issue. The first step is to inspect the bushings for visible wear or damage visually. Look for cracks, tears, or other signs of damage. If the bushings are visibly worn or damaged, this is a good indication that they need to have a replacement.

Another way to diagnose sway bar bushing problems is to test drive the vehicle and pay attention to unusual noises or handling issues. If you hear creaking, knocking, or clunking noises while turning or driving over bumps, or if your vehicle feels loose or unstable while driving, this could be a sign of faulty sway bar bushings.

It’s also good to check for worn sway bar links or other suspension components, which can contribute to sway bar bushing failure. If you find that your sway bar links are worn or damaged, they may need to have a replacement along with the sway bar bushings.

If you’re unsure whether your sway bar bushings are faulty or unable to diagnose the issue, it’s a good idea to have a mechanic diagnose the problem. They will be able to identify the cause of the problem and recommend the appropriate course of action.

Diagnosing sway bar bushing problems is important because it allows you to address them before they become a larger problem. Ignoring faulty sway bar bushings can further damage your suspension system and negatively impact the handling and safety of your vehicle. Be sure to have the issue diagnosed and repaired by a mechanic as soon as possible.

How to fix sway bar bushing problems

If you’ve diagnosed a problem with your sway bar bushings, there are a few options for fixing the issue. The most straightforward option is to replace the sway bar bushings. This typically involves jacking up the vehicle and removing the old bushings, then installing new ones in their place.

Replacing sway bar bushings is a relatively simple process that a mechanic or an experienced DIY enthusiast can do. However, it’s important to follow the manufacturer’s instructions and use the correct tools to ensure that the job is correctly set.

Another option for fixing sway bar bushing problems is to upgrade to performance sway bar bushings. Performance sway bar bushings are more durable and offer improved handling and reduced noise compared to stock sway bar bushings. If you’re looking to improve the handling and performance of your vehicle, upgrading to performance sway bar bushings is a good option.

Regardless of your choice, it’s important to address sway bar bushing problems as soon as possible. Neglecting faulty sway bar bushings can further damage your suspension system and negatively impact the handling and safety of your vehicle. Be sure to have the issue diagnosed and repaired by a mechanic as soon as possible.

In conclusion, sway bar bushings are an important component of a vehicle’s suspension system that helps to maintain stability and handling. Diagnosing and fixing the issue as soon as possible is important if you’re experiencing symptoms of faulty sway bar bushings, such as noise, handling issues, or visible wear or damage. You can either replace the sway bar bushings or upgrade to performance sway bar bushings to improve handling and reduce noise. By promptly addressing sway bar bushing problems, you can ensure the safety and performance of your vehicle.

Upgrading to performance sway bar bushings

In addition to replacing faulty sway bar bushings with new ones, another option to consider is upgrading to performance sway bar bushings. Performance sway bar bushings are designed to be more durable and offer improved handling and reduced noise compared to stock sway bar bushings.

Improved handling

There are a few benefits to upgrading to performance sway bar bushings. One of the main benefits is improved handling. Performance sway bar bushings are typically firmer and more rigid than stock bushings, which helps to reduce body roll and improve stability when turning. This can make a noticeable difference in handling your vehicle, particularly when driving at high speeds or on winding roads.

Reduced Noise

Another benefit of performance sway bar bushings is reduced noise. Stock sway bar bushings are typically made of rubber, which can produce creaking or knocking noises as they age or become damaged. Performance sway bar bushings have polyurethane or other materials less prone to producing noise. This can make for a quieter and more comfortable driving experience.

Improved performance

Upgrading to performance sway bar bushings is a good option to consider if you’re looking to improve the handling and performance of your vehicle. However, it’s important to remember that performance sway bar bushings may be firmer and transmit more road noise than stock bushings. This may not be suitable for everyone, so weighing the pros and cons is important before deciding whether to upgrade.

If you do decide to upgrade to performance sway bar bushings, the process is similar to replacing stock sway bar bushings. You’ll need to jack up the vehicle and remove the old bushings, then install the new performance bushings in their place. A mechanic or an experienced DIY enthusiast can typically do this process. It’s important to follow the manufacturer’s instructions and use the correct tools to ensure the job is safe and correct.

Upgrading to performance sway bar bushings can be a good way to improve the handling and performance of your vehicle. While there may be some trade-offs in terms of increased road noise and firmer rides, the benefits of improved handling and reduced noise can be well worth it for many drivers. If you’re considering upgrading to performance sway bar bushings, be sure to do your research and choose a reputable brand to ensure the best possible results.

Steps for replacing sway bar bushings

If you’ve diagnosed a problem with your sway bar bushings and decided to replace them, there are a few steps you’ll need to follow to ensure that what you will do is safe and correct.

The first step in replacing sway bar bushings is to gather the necessary tools and supplies. You’ll need a jack and jack stand or a hydraulic lift to lift the vehicle off the ground, a lug wrench to remove the wheels and various hand tools such as a wrench or socket set to remove the old bushings and install the new ones. You’ll also need a new set of sway bar bushings, which you can purchase from an auto parts store or online. Be sure to choose a reputable brand and ensure that the bushings are compatible with your specific make and model of vehicle.

Once you have everything, you can start replacing the sway bar bushings.

Genera steps

- Lift the vehicle off the ground: Use a jack and jack stand or a hydraulic lift to lift the vehicle off the ground. Make sure that the vehicle is secure and stable before you start working on it.

- Remove the wheels: Use a lug wrench to remove the wheels from the vehicle. This will give you better access to the sway bar bushings.

- Remove the old sway bar bushings: Use a wrench or socket set to remove the mounting hardware for the sway bar bushings. Once the hardware is removed, you should be able to pull out the old bushings. Be careful not to damage the sway bar or other components as you remove the old bushings.

- Install the new sway bar bushings: Once you remove the old bushings, you can install the new ones. Follow the manufacturer’s instructions for installing the new bushings, use the correct tools, and torque the mounting hardware to the recommended specifications.

- Reinstall the wheels: Once you have installed the new sway bar bushings, you can reinstall the wheels and lower the vehicle back to the ground. Make sure that you will tighten the wheels to the recommended torque specification.

- Test drive the vehicle: After replacing the sway bar bushings, it’s a good idea to test drive the vehicle to ensure everything is functioning correctly. Pay attention to any unusual noises or handling issues, and make necessary adjustments.

Replacing sway bar bushings is a relatively simple process that a mechanic or an experienced DIY enthusiast can typically do. If you’re not comfortable replacing the sway bar bushings, you can have a mechanic do it. Either way, it’s important to address sway bar bushing problems as soon as possible to ensure the safety and performance of your vehicle.

Conclusion: The Importance of Maintaining Sway Bar Bushings for Vehicle Safety and Performance

Sway bar bushings are an important component of a vehicle’s suspension system that helps to maintain stability and handling. If you’re experiencing symptoms of faulty sway bar bushings, such as noise, handling issues, or visible wear or damage, diagnosing and fixing the issue as soon as possible is important. You can either replace the sway bar bushings or upgrade to performance sway bar bushings to improve handling and reduce noise.

If you choose to replace the sway bar bushings, the process involves jacking up the vehicle and removing the old bushings, then installing new ones in their place. A mechanic or an experienced DIY enthusiast can typically do this process.

Upgrading to performance sway bar bushings is another option to consider if you’re looking to improve the handling and performance of your vehicle. Performance sway bar bushings are more durable and offer improved handling and reduced noise compared to stock sway bar bushings. However, it’s important to remember that performance sway bar bushings may be firmer and transmit more road noise than stock bushings. This may not be suitable for everyone, so weighing the pros and cons is important before deciding whether to upgrade.

In conclusion, sway bar bushings are an important component of your vehicle’s suspension system that plays a critical role in maintaining stability and handling. If you’re experiencing faulty sway bar bushings symptoms, be sure to have the issue diagnosed and repaired by a mechanic as soon as possible. By promptly addressing sway bar bushing problems, you can ensure the safety and performance of your vehicle.

Frequently Asked Questions about the symptoms of Sway Bar Bushing.

What are sway bar bushings, and what do they do?

Sway bar bushings are a component of a vehicle’s suspension system. They isolate the sway bar from the frame and absorb shock as the vehicle travels over uneven roads. Sway bar bushings help maintain the vehicle’s stability and handling, particularly when turning or driving over bumps.

What are some common symptoms of faulty sway bar bushings?

Some common symptoms of faulty sway bar bushings include creaking, knocking, or clunking noises while turning or driving over bumps, handling issues such as the vehicle feeling loose or unstable while driving, and difficulty maintaining control in turns. Sometimes, sway bar bushings may also be visibly worn or damaged.

What are the causes of sway bar bushing failure?

Over time, the most common cause of sway bar bushing failure is wear and tear. Sway bar bushings are subjected to a lot of stress and movement as the vehicle travels over uneven roads, and this can cause them to wear out over time. Other causes of sway bar bushing failure include damage from road debris or accidents, incorrect installation, and lack of lubrication.

How do I diagnose sway bar bushing problems?

You can start by visually inspecting the bushings for visible wear or damage to diagnose sway bar bushing problems. You can also test drive the vehicle and pay attention to unusual noises or handling issues.

How do I fix sway bar bushing problems?

To fix sway bar bushing problems, you can either replace the sway bar bushings or upgrade to performance sway bar bushings. Replacing sway bar bushings involves jacking up the vehicle and removing the old bushings, then installing new ones in their place.